Release time:2024-10-29

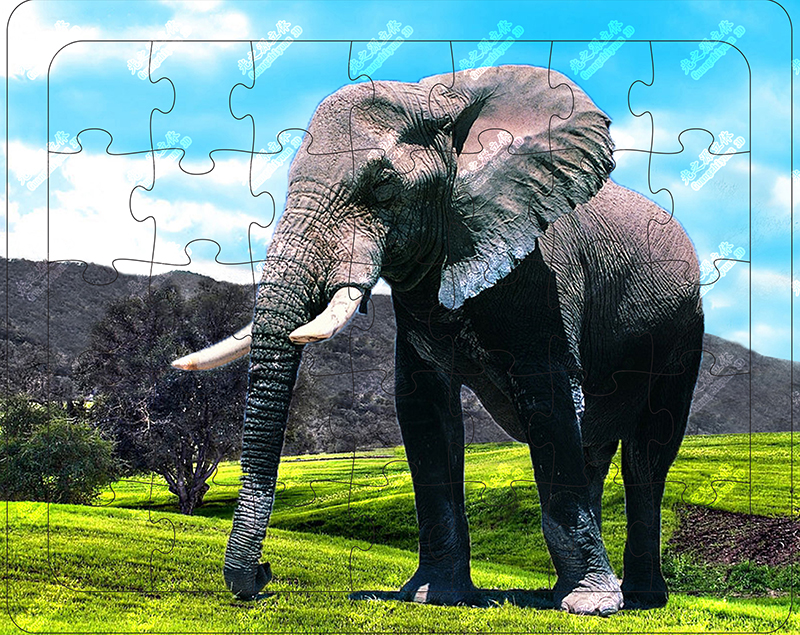

3D lenticular puzzles have captured the fascination of puzzle enthusiasts with their stunning visual depth and dynamic imagery. These puzzles add an engaging twist to traditional puzzles by using lenticular printing technology to create an illusion of motion or depth, making images appear to change when viewed from different angles. At Guangzhiyuan, we specialize in the detailed process of manufacturing 3D lenticular puzzles that captivate and delight. Here, we explain the key steps in producing these unique puzzles and what makes them so visually compelling.

The manufacturing of a 3D lenticular puzzle begins with selecting and preparing the images that will form the basis of the lenticular effect. This step is critical, as the selected image will determine the puzzle's visual impact. Lenticular puzzles typically involve two types of effects:

3D Depth Effect: Creates the illusion of depth, making the image appear three-dimensional.

Flip and Animation Effects: Produces an image that appears to change or move when viewed from different angles.

To achieve these effects, multiple images or frames are required. The images are then layered and digitally processed to create a composite file ready for lenticular printing.

Once the images are selected, they must be interlaced. This process involves combining multiple images into a single file, with each image broken down into fine strips. The strips are then interwoven together, creating a layered effect. Interlacing is essential for the lenticular effect, as it allows the different frames or perspectives to be displayed based on the angle of viewing. Special software is used to achieve this, ensuring that the images align precisely to produce a seamless transition when viewed on a lenticular lens.

After the images are interlaced, the next step is printing the composite image onto a lenticular sheet. Lenticular sheets are made from transparent plastic with a series of lenses or ridges that create the 3D and motion effects. The interlaced image is printed on the back of this lens sheet, aligning with the ridges on the sheet to control the angle at which each image is visible. There are two main printing methods used:

Digital Printing: Suitable for shorter runs, digital printing is ideal for producing high-resolution, small-batch orders. This process offers flexibility in modifying the design and is often preferred for custom lenticular puzzles.

Offset Printing: Typically used for larger production runs, offset printing provides vibrant colors and precise detailing, making it ideal for high-quality 3D lenticular puzzles.

Alignment is crucial for the 3D effect to work effectively. Misalignment can cause the image to blur or disrupt the intended visual effect, so meticulous attention to detail is necessary at this stage. Each printed sheet is inspected for accuracy, color fidelity, and alignment with the lenticular lens. Guangzhiyuan’s quality control process includes checking each puzzle piece to ensure it aligns with the overall image, maintaining visual clarity and impact.

Once the printed lenticular sheet passes quality control, it is cut into puzzle pieces. Die-cutting machines are used to cut the sheet into precisely shaped puzzle pieces that interlock perfectly. Due to the thicker lenticular sheets, die-cutting must be done with specific equipment designed to handle the unique material without damaging the printed image or the lenticular lens.

The cutting process also requires precision to ensure that each puzzle piece contains a segment of the 3D image that aligns with the others, so the completed puzzle maintains its intended depth or motion effect. This precision cutting is vital to the final assembly experience, ensuring a smooth interlocking of the pieces.

After the pieces are cut, they are packaged for shipment. Guangzhiyuan prioritizes protective packaging to prevent scratches or damage to the lenticular lens, as even minor damage can affect the visual effect. Packaging includes:

Protective Wrapping: Each piece is carefully packed to protect the lenticular surface from scratches and to maintain the integrity of the effect.

Instructions and Image Guide: Since lenticular puzzles are more complex than traditional puzzles, packaging often includes an image guide to help users see the completed puzzle image before assembling it.

Before distribution, a final quality check is conducted to ensure that each 3D lenticular puzzle meets Guangzhiyuan’s standards for clarity, depth, and durability. Our goal is to deliver a product that provides an enjoyable and immersive experience, and the final inspection guarantees that the lenticular effect works as intended when assembled.

At Guangzhiyuan, our expertise in lenticular technology allows us to create puzzles that stand out in both visual appeal and quality. Our manufacturing process combines precision, advanced printing technology, and rigorous quality control to ensure each puzzle delivers a unique 3D or animated experience. By investing in top-quality materials and meticulous design, Guangzhiyuan ensures that each lenticular puzzle provides both a satisfying assembly experience and an engaging visual payoff.

Creating a 3D lenticular puzzle requires careful planning, advanced technology, and skilled craftsmanship. From image selection to interlacing, printing, and die-cutting, each step in the manufacturing process is essential to achieving the final product's mesmerizing effect. Guangzhiyuan’s commitment to quality in the production of 3D lenticular puzzles guarantees that each piece is a work of art, ready to captivate and entertain. Whether you’re looking to create custom designs or enjoy our ready-made options, Guangzhiyuan is dedicated to delivering puzzles that inspire and delight puzzle enthusiasts worldwide.

Pre:Product Lifespan of Lenticular Lens Sheets in Outdoor Displays

Guangzhiyuan 3D Technology Co., Limited

Address: No.285, Jinou Road, Jianghai District, Jiangmen City, Guangdong Province

Contact information:13528341661, Contact person: +86-13318647023, Technical person: +86-13528341661

Wechat : enjoy everyday, Whatsapp: +86-13528341661, Skype: ada16825

technical support:sharebd icp:粤ICP备2022109877号

Hotline

Scan