Release time:2024-11-12

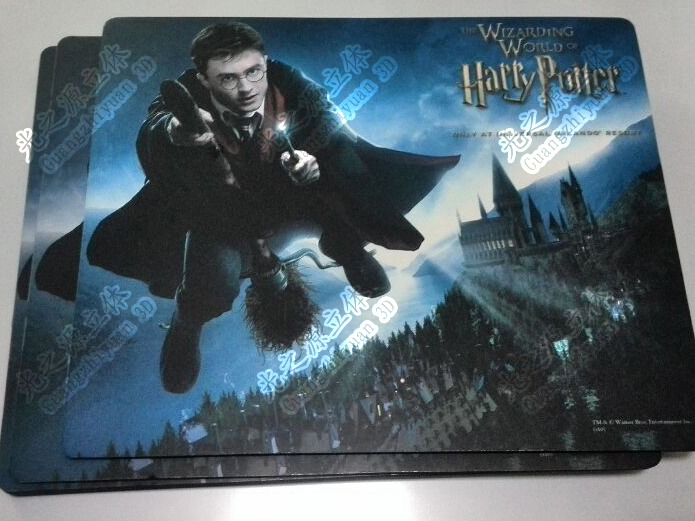

As lenticular printing grows in popularity for advertising, packaging, and entertainment, price dynamics in the industry are shifting. Lenticular printing is valued for its ability to create engaging 3D effects and animations, making products stand out on crowded shelves and in digital spaces. For Guangzhiyuan, a leading name in lenticular printing services, staying attuned to price trends is crucial for delivering competitive, high-quality products. This article provides an overview of the current price trends in lenticular printing services, explores how Guangzhiyuan compares to peer companies, and examines industry factors influencing these trends with specific numerical parameters.

To understand price trends in lenticular printing, it’s essential to look at the factors that influence costs in this industry:

Material Costs:

Lenticular printing requires specialized materials such as PET, PMMA, and polycarbonate. Material choice affects both quality and durability, with prices for these materials fluctuating based on global supply chains. For instance, the cost of PET material, often chosen for its clarity and recyclability, can range from $1.50 to $2.50 per square meter, depending on bulk purchase quantities and market conditions.

Production Technology:

Printing technology impacts the cost. Digital printers and offset printers are commonly used, with the former offering more flexibility for smaller runs and custom designs. Digital printing setups are typically $25,000–$100,000, while offset printing requires investments up to $250,000, influencing production costs and scalability.

Customization and Finishing:

Customizations, such as die-cutting, coating, and UV treatments, are added costs. Customization adds approximately 15–20% to the base cost, with a typical finishing cost ranging from $0.10 to $0.50 per unit.

Labor and Expertise:

The precision required for lenticular printing demands skilled labor. Labor costs in high-quality lenticular printing typically add 10–15% to total production costs.

Order Volume:

Bulk orders reduce per-unit costs due to economies of scale. For instance, orders under 1,000 units might average $3–$4 per unit, while orders of 10,000+ units can reduce the price to around $1.50 per unit.

Guangzhiyuan positions itself in the market by balancing competitive pricing with quality assurance, focusing on high-end materials and precision technology. Here’s a comparative analysis of Guangzhiyuan’s pricing strategies relative to industry peers.

| Company | Typical Material Cost (per sq. meter) | Production Cost per Unit (1,000 units) | Customization/Finishing Add-Ons |

|---|---|---|---|

| Guangzhiyuan | $1.70–$2.20 | $3.00–$4.00 | $0.15–$0.45 |

| Competitor A | $1.50–$2.00 | $2.50–$3.80 | $0.10–$0.40 |

| Competitor B | $1.20–$1.80 | $2.20–$3.50 | $0.08–$0.35 |

| Competitor C | $1.80–$2.50 | $3.20–$4.50 | $0.20–$0.50 |

Guangzhiyuan offers competitive pricing on high-end PET and PMMA materials and utilizes digital printing for small-to-medium runs, allowing flexibility for customizations and premium finishing without exceeding market rates. This places Guangzhiyuan slightly above budget providers in terms of cost but aligns with other premium providers, maintaining a strong balance between quality and price.

Several industry trends are impacting the pricing landscape in lenticular printing, many driven by advancements in technology, material sourcing challenges, and shifting consumer demand:

Growing Demand for Eco-Friendly Materials

Sustainable options, such as recyclable PET, have become a major focus, driving up costs slightly as companies respond to consumer demands for greener alternatives. This has led to a 5–10% rise in the cost of PET over the past two years. Guangzhiyuan’s dedication to environmentally conscious materials positions it favorably, especially among consumers willing to pay slightly more for sustainable products.

Digital Printing Technology Adoption

Digital printing technology has made it possible to produce high-quality lenticular prints in smaller, more customized runs. This trend favors companies like Guangzhiyuan, which leverage digital technology to offer custom services without the high setup costs of offset printing. The technology itself, while lowering per-unit costs for small orders, comes with initial investment costs that affect overall pricing, especially for new entrants.

Price Fluctuations in Raw Materials

Due to global supply chain disruptions, prices for raw materials such as PMMA and polycarbonate have seen fluctuations. For instance, polycarbonate prices have increased by about 8% over the last year, driven by increased demand and limited supply. Guangzhiyuan, like many in the industry, has needed to adjust prices on products using polycarbonate, particularly for high-impact, durable outdoor displays.

Customization Demand in Advertising and Packaging

Customization has become a standard expectation in lenticular printing, especially within the packaging and advertising sectors. Clients are requesting more intricate designs, often with multiple effects like 3D depth, flip, and morph. This demand raises production costs, as each effect requires precise lens alignment and more sophisticated printing techniques. This trend has led to a 10–20% increase in the price for customized lenticular products.

Regional Price Variations

Regional differences in material access and labor costs create price variability across markets. In North America, for example, lenticular printing costs are generally higher by around 15% compared to Southeast Asia, where material sourcing and labor are more cost-effective. Guangzhiyuan’s strategic location allows it to offer competitive pricing for both regional and global clients by leveraging local resource advantages.

The lenticular printing industry is expected to grow at an annual rate of 6% over the next five years, with demand for specialized materials and digital printing on the rise. Pricing trends will likely continue to reflect this growth, with specific areas of change predicted:

Decreasing Digital Printing Costs:

As digital printing technology matures, per-unit production costs are anticipated to decrease by 5–10% over the next five years, especially for customized small-volume orders.

Sustainability Premium:

Environmentally-friendly material sourcing may continue to increase in cost, with a projected 3–5% annual rise in the cost of recyclable plastics like PET. Companies prioritizing eco-friendly options, like Guangzhiyuan, may shift to a premium pricing strategy to cover these rising material costs.

Increased Customization Demand:

Demand for intricate, multi-effect printing will likely keep customization costs high, projected to add up to 25% of the base production cost. As brands continue to seek unique, engaging designs, lenticular printing providers will need to invest in advanced equipment and skilled labor to meet these needs.

With price dynamics in lenticular printing shaped by technology, material sourcing, and customization demand, companies like Guangzhiyuan are balancing cost competitiveness with premium quality. By leveraging high-end materials and sustainable options, Guangzhiyuan positions itself as a premium provider, aligning with industry trends and responding to consumer expectations.

Understanding these price trends allows clients to make informed decisions about their lenticular printing projects, ensuring the best balance between cost and quality. As the industry grows and technology advances, companies like Guangzhiyuan will continue to shape the landscape, meeting rising expectations for both quality and sustainability.

Pre:Materials Guide for 3D Soft Lenticular Printing

Guangzhiyuan 3D Technology Co., Limited

Address: No.285, Jinou Road, Jianghai District, Jiangmen City, Guangdong Province

Contact information:13528341661, Contact person: +86-13318647023, Technical person: +86-13528341661

Wechat : enjoy everyday, Whatsapp: +86-13528341661, Skype: ada16825

technical support:sharebd icp:粤ICP备2022109877号

Hotline

Scan